This text compares cotton and foam drop-in air filters for vehicles, highlighting their unique benefits. Cotton filters trap tiny particles while maintaining airflow, ideal for efficiency, while foam filters offer robust protection against contaminants and high temperatures, suitable for powerful engines. Both materials cater to distinct vehicle needs, enhancing performance through optimized filtration and engine health. When choosing a drop-in air filter, consider your vehicle's specific requirements for optimal results.

When it comes to improving indoor air quality, choosing the right drop-in air filter is essential. This article delves into the heart of two popular options: cotton and foam. We explore their unique materials and compositions, analyzing how their physical properties impact filtration efficiency. Through performance testing and real-world applications, we weigh their effectiveness in capturing particles and allergens. Additionally, we dissect their durability, maintenance demands, and cost implications to help you make an informed decision for your home or office.

- Materials and Composition

- – Detailed look at cotton and foam as filter media

- – Comparison of their physical properties and how they affect filtration

Materials and Composition

When it comes to drop in air filters, the primary distinction lies in the materials and composition of the filter media. Cotton and foam are two commonly used materials, each offering unique advantages for improving airflow and engine performance. Cotton filters, often favored by enthusiasts, are crafted from natural cotton fibers, known for their softness and flexibility. This material is effective at trapping fine particles and dust without restricting airflow, making it ideal for those looking to enhance their vehicle’s overall efficiency.

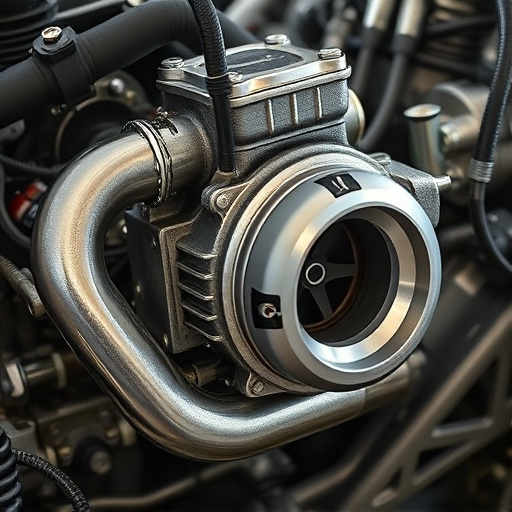

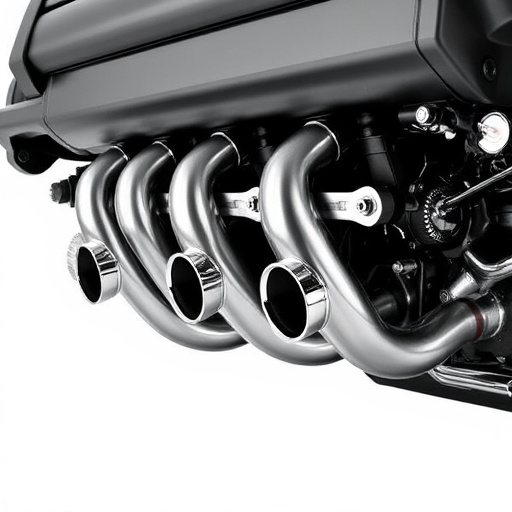

On the other hand, foam drop-in air filters utilize a synthetic foam material that provides an efficient barrier against contaminants found in the air entering your engine. Unlike cotton, foam filters are less susceptible to moisture absorption and can handle higher temperatures, making them suitable for vehicles with powerful engines or those equipped with cold air intakes and exhaust mufflers. High-performance parts require robust filtration, and foam filters often meet these demands effectively.

– Detailed look at cotton and foam as filter media

Cotton and foam are two distinct materials used in drop-in air filters, each with unique properties that impact performance and longevity. Cotton, a natural fiber, has long been a staple in filter media due to its exceptional filtration capabilities and durability. The intricate network of cotton fibers effectively captures tiny particles, including dust, pollen, and even some toxins, ensuring cleaner air enters your vehicle’s engine. This material is known for its ability to withstand high temperatures and pressure, making it suitable for demanding environments.

On the other hand, foam filters offer a lightweight yet robust alternative. Made from synthetic materials, these filters are designed to provide excellent airflow while still trapping contaminants. The porous structure of foam allows for efficient air flow, which is beneficial for maintaining optimal engine performance. Moreover, foam filters can be shaped and sized to fit various drop-in air filter applications, including those found in performance vehicles where both powerful engines and reliable braking systems, like high-performance brake pads, are employed. This versatility makes them a popular choice for enthusiasts seeking enhanced performance air filters.

– Comparison of their physical properties and how they affect filtration

When comparing cotton vs. foam drop-in air filter materials for your vehicle’s drop in air filter kit, understanding their physical properties is key to optimal filtration performance. Cotton filters are known for their high capacity and durability, capable of trapping finer particles due to their dense, fibrous structure. This makes them ideal for high-flow applications and providing excellent dust and debris protection, especially in harsh environments. On the other hand, foam filters offer a unique combination of efficiency and breathability. The open-cell structure allows for maximum airflow while still capturing contaminants, ensuring your engine receives a steady stream of clean air. This property is particularly beneficial for brake components that require consistent performance.

The physical properties of these materials directly impact the filtration process. Cotton’s rigidness and thickness provide robust protection against large particles, making it suitable for heavy-duty applications. Foam, with its flexibility and lightweight design, delivers efficient dust removal without restricting airflow, ensuring your vehicle’s engine and high performance parts remain unburdened. Whether you opt for cotton or foam, selecting the right material aligns with your specific driving needs, contributing to a more efficient and powerful engine performance.

When it comes to drop-in air filters, both cotton and foam offer unique advantages. Cotton’s natural fibers provide excellent airflow and a high dust-capturing capacity, making it an eco-friendly choice. Foam, on the other hand, boasts superior oil hold capacity and water resistance, ensuring prolonged filter life. The ideal selection depends on specific needs; for optimal dust reduction, cotton is a top pick, while foam excels in environments requiring increased oil and moisture control. Choosing between these materials allows homeowners to tailor their air filtration to their unique circumstances, contributing to cleaner, healthier indoor air.